Diptrace Create Component

Building the Nelson Pass ACA PCB with Diptrace In 2013 I evaluated Diptrace 2.3 and found it to be reasonably capable for the price but hamstrung with a very poorly designed library manager. For that reason I wound up declining to buy the software at that time and went on to other projects. When I learned in late 2014 that Novarm had released version 2.4 which incorporated a completely new library manager I decided to evaluate the software again and use it to complete a real project I was working on at the time: a new layout of the Amp Camp Amp (ACA) #1 circuit designed by Nelson Pass. This article aims to explain my first experiences with Diptrace and my related efforts to produce a revised ACA PCB.

Jul 11, 2016 - The solution is to create a custom PCB that will serve both as a fixing. DipTrace includes many standard components such as terminal blocks. The developers provide a multi-lingual interface and tutorials (currently available in English and 21 other languages). DipTrace has 4 modules: schematic capture editor, PCB layout editor with built-in shape-based autorouter and 3D-preview & export, component editor, and pattern editor.

For more information about the chassis I developed for this PCB check out my. Background When Nelson released the for the ACA he was kind enough to provide ready-made PCBs and work with the fine folks at to distribute not only the PCBs but including a monoblock chassis that leveraged an external, off-the-shelf switch mode power supply (SMPS) to provide the required 19V and 2 amps (one supply per channel). Less than ideal for audio applications, the SMPS was clearly chosen for reasons of cost and safety, as the target for this amplifier is first-time builders. Several advanced users who decided to build the amp for fun reported improvements in sound quality and 'depth', particularly at low frequencies, when the SMPS was replaced with a sufficiently capable linear supply. Each channel of the diyaudio-produced chassis incorporated a 80x200mm heatsink which proved adequate for the design and the required 20W per channel dissipation (note: this is a 6W Class A amp and thus inefficient: dissipation is roughly 3X the rated power output), though some users reported that the heatsinks could get pretty toasty, particularly if operated in higher ambient temperatures.

The original ACA PCB would not fit on the 2U heatsink without modifications. I did not want to move the board up since that would have covered the screw used to secure the heatsink bracket. Courtesy of a diyaudio member, this closeup shows the R15 mod as applied to the original ACA PCB. Mods of this type are difficult even for those with some soldering experience. I decided to avoid it altogether. I'm spoiling the surprise here but this is what I aimed to achieve with my PCB - board and FETs nicely spaced on the heatsink and all mounting screws easily accessible, including those of the heatsink. In order to address both the power supply and dissipation issues I decided to import a 2U 300mm deep chassis from HiFi2000, known on the web as modushop.biz.

This larger (but still slender) chassis provided a slightly larger heatsink (80x300mm) and significantly more internal volume as required to incorporate the dual mono linear supplies with, and I planned to integrate. As more users began to build the ACA several noted it did not meet the original power specifications.

Nelson eventually came out with a fix that involves adding a new resistor whose reference designator is R15. This version of the circuit is referred to as Version 1b. At the time I started this project I fully expected to use the original Version 1 PCBs and apply the R15 fix but I realized I'd need to come up with a different solution for a couple reasons:. When I attempted to orient the PCBs on the heatsink of the new chassis it quickly became apparent that the mounting rails that bind the heatsinks to the top and bottom covers would conflict with the FETs hanging off the bottom of the PCB. I could have hacked a section out of the rails to make it work but then I'd still be left with the FETS being perilously close to the edge of the heatsinks.

While that's the way it's done in the diyaudio chassis primarily due to space and cost constraints, it's sub-optimal; heatsink simulation shows that for passively cooled applications it's best to position devices spread out on a centerline positioned just below the midline of the heatsink to ensure optimal dissipation. I decided to address this by relocating the FETs to the sides of the boards. The PCB mounting holes were constructed as vias (plated through holes) and made part of the signal ground. That's perfectly fine if you're building monoblocks (i.e.

One PCB per chassis), but practically guaranteed to produce ground loops and the associated noise (hum/hiss) if two PCBs are deployed in the same chassis. I thus knew my layout would have to isolate the mounting holes / vias from the circuit ground. While I was at it, I also figured I'd address a few other shortcomings:. The R15 fix. It seemed wise to formally integrate the fix so that no delicate soldering technique would be required. It would also make future tweaking of the resistor value easier.

Otherwise I'd have to apply the original fix which involved soldering the resistor lead directly to the lead of a TO-92 package transistor, placing it at increased risk of heat damage. Several people reported that the single-turn potentiometer used to set the bias voltage was incredibly sensitive and made trimming the bias difficult. I figured that I'd integrate a multi-turn pot to solve this issue. All of Nelson's other designs usually incorporate multi-turn pots so I'm not sure why he chose this part exactly but my guess is cost.plain and simple.

While many on diyaudio espouse the benefits of single-point grounding on audio PCBs and I can relate to their arguments, as an amateur radio operator I tend look at everything as an RF project and every trace on a PCB as a potential antenna. I'm therefore partial to many of the techniques used in the design of RF equipment to eliminate radiation or susceptibility to external radiation sources. One such technique is the use of a groundplane in order to reduce ground impedance. Malayalam kambi kathakal latest. Ground planes can also serve a secondary role as a shield but in this case I was under no illusion that would be of any value here, particularly because that function suffers considerably the second you start poking holes in the plane as required in a through-hole design.

Still, my goal was to lay out as solid a plane as possible and see what happens. After all, experimentation is part of the fun. Schematic Capture I found Diptrace's schematic capture program to be fully functional and easy to use. The basic drawing tools worked intuitively and I never had to ask why or how something worked.it just did, and that's the sign of good application design. The new library manager was instantly recognizable and it allowed me to quickly select components from either the standard libraries or my privately developed libraries that Diptrace calls 'User' libraries.

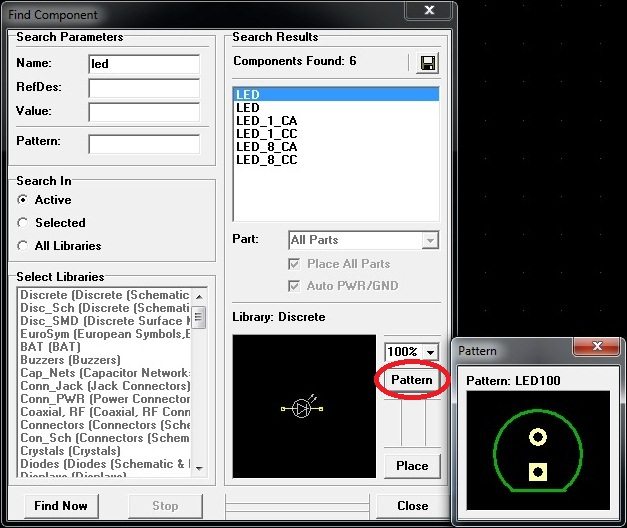

It also allowed me to easily copy patterns or components from the standard libraries into my own libraries so I could save time, for example, by reusing a standard package footprint (TO92, TO220, etc.) but incorporate my own schematic symbol and 3D model into the part. All in all this is a huge win for Diptrace and the primary reason I decided to buy a license for the tool. Building Components If a required component is not one of the 90K or so available in the standard libraries a custom component must be produced.

I wound up building a few components and found the experience to be mostly trouble-free but not without a few challenges. The original ACA PCB assumed the user would solder wires directly to the board but I've found that it's not particularly easy to solder heavy gauge wires that act as an effective heatsink so I decided to use a Keystone screw terminal. I first learned about the Keystone terminals when building the diyaudio soft start board and instantly saw the benefit of these over wires or even traditional TE Faston blades. Faston blades are popular because they're inexpensive and simple but their function depends on a friction fit with their mating components. Unfortunately I have found on other projects that mating and unmating these connections places undue stress on the PCB, particularly if the blades are placed too far away from the board's structural supports (standoffs). This stress can induce fractures in the PCB substrate, lift surface mount devices off the board and, more dangerously, short through hole component leads to the chassis.

Removing a mating ring terminal from the Keystone connector, on the other hand, requires only a screwdriver and places no stress on the board. The Keystone terminal was not among the standard libraries so I had to build a custom component for it. In most cases building custom components is a straightforward process but the Keystone connector proved to be a bit more challenging. A device typically has a number of pins or leads coming out of it, each of which serve a particular function, so the goal is to create a pattern in the Pattern editor with an equivalent number of pads (for a surface mount part) or vias (for a through-hole part).

Then, in the Component editor the same number of pins is created, each of which is assigned to a specific pad or via in the pattern. The problem with the Keystone part is that while it required 6 vias, all of those vias had to be assigned to the same component pin (its only pin, in fact).

It wasn't initially obvious to me how to do this but some research revealed the solution: in the Component editor's pin-mapping dialog draw a rat line from the pin to the first via, and then additional rat lines from that via to an adjacent via, from that via to the next via, and so on until all vias are assigned. I initially thought I could reuse this newly-created component for multiple signals ('IN', '+19V', '+OUT', and '-OUT') and merely change its name as required. I did in fact attempt this and managed to integrate four instances of these components in the schematic only to discover, once I'd transitioned into the PCB editor, that the resulting rats nest contained connections between these obviously conflicting signals.

This was the result of the schematic program assigning all four of these connectors to the same net. That forced me to create individual components, each with appropriate names. After I replaced the old components in the schematic with the specialized versions and refreshed the design from the schematic in the PCB editor the bogus rat lines disappeared. I'm still not sure why this didn't work as expected but I got the job done anyway and there's something to be said for specializing every component - it typically makes creating the BOM a bit easier. This is how I managed to map one component pin to multiple vias in the Diptrace pattern editor. The extra two vias allow substitution with TE Connectivity Faston blades. One of the best features of Diptrace is its support for importing 3D models in STEP format.

I got this 3D model directly from Keystone's website and tweaked the offset values to position it relative to the pads. I had difficulty selecting the proper traces in my multi-layer component and changing the Display Side menu setting from Contrast to Current Only served as a fix. The last issue I encountered was specific to the pattern editor.

It supports the concept of drawing layers so it's possibile to manipulate traces drawn simply by selecting (or merging) layers, much as you would in a common image manipulation program such as Photoshop or GIMP. The problem is that's where the similarity ends. I kept trying to select one particular trace on the currently-selected layer and that wound up selecting a trace directly below it on the Bottom layer instead. Borrowing on my experience with the aforementioned image programs I tried looking for a 'hide layer' feature but never found it. Diptrace support suggested that the solution was to click once to select the top trace and twice to select the bottom trace but that didn't work to me.

I'll spare you a rant about how this is completely nonintuitive and merely offer that I ultimately solved the problem by selecting View→Display Side→Current Only. This effectively hid all layers other than the currently selected layer and allowed me to select the traces I needed. The downside? Hidden layers appear blank in the layers pane and I accidentally assumed at one point that the blank layer was the result of a previous layer merge and was no longer needed so I deleted it. I soon realized the problem and was forced to reselect that layer and recreate all the traces.

My advice to the developers: gray out the content on hidden layers - don't make the content appear blank! The most annoying aspect of building patterns and components in Diptrace is the need to constantly switch back and forth between the Component and Pattern editor programs.

While I can appreciate the reasons why the developers might prefer to keep these applications separate (simpler UI, easier to test prior to release, etc.) they're so closely functionally related that in my opinion they should be combined. I hope Novarm integrates these applications in a future release. Forward and Back Annotation For those unfamiliar with the terms: Forward annotation is the process of sending schematic changes to a corresponding PCB layout program. Back Annotation is the process of sending changes made to the circuit in the PCB layout program back to the schematic. For this project I did not use or test Back Annotation, though Diptrace apparently supports it. I did, however, make many changes to the schematic and later send those updates to the PCB editor with ease.

Welcome to the next generation of PCB library development. The Library Expert is the original IPC footprint automation solution, which is also flexible enough for the most advanced user-defined modifications to effortlessly create footprints from component data. It outputs individual parts or entire libraries to all major CAD formats (each available separately). Here is what you get with the CAD output for DipTrace license:. Output to format readable by DipTrace. Our advanced CAD LEAP TM Technology (Libraries Enhanced with Automated Preferences).

complimentary access (over 1 million parts). Set of unique component packages that may be used with well over 300,000 parts!. Complimentary access to our. New part requests, regardless complexity, as little as $5 each. 12 Months of updates included!. Ability to create footprints with arbitrary pad shapes and positions. Low cost & FASTEST return on investment.

High priority phone, email, or shared desktop support. Perpetual license does not expire; no maintenance. 1 Year maintenance renewal is 24% the list cost of license(s). FREE training webinars as needed, one-on-one or group. Add and modify library documentation. User definable preferences or define and customize default rules wow!!.

Save component dimensions to a library file. Search, edit, save functions for effective part library management. Flexibility to add, delete, or modify data fields - for example:. Corporate Part Number. Schematic Symbol Name. Created By / Date.

Purchased From. Bulk / Piece Price. DigiKey Part Number. Project Name. etc.

(no limit!). Complimentary access to POD lasts while user has latest released major version (eg. V2015, v2016, etc); latest version is highly recommended as POD data format is periodically updated to accomodate new Library Expert features. New part requests are $5 for 99% of the parts; really complex parts that take more than 2 hours to build will be charged double. PLUS all the features of the FREE Library Expert 'Pro' edition, which include:. Pin rename & renumber. Calculate high resolution footprints directly from component dimensions.

IPC-7351 compliant. Enter component dimensions using Nominal plus tolerance or Min/Max dimensions. Automate creation of component manufacturer recommended footprints. One-click rotate/mirror footprint, very useful for rapid LGA/BGA design wow!!. One-click pad shapes supported: Rectangle, Oblong, D-Shape, and Rounded Rectangle.

Dynamic support for Imperial and metric - easily convert between mil and metric units. Convert units calculator. Apply rules to component families and component terminal lead types. User friendly GUI easy to learn.

Padstack editor. Email & forum support.and more!! We built the Library Expert around the notion that there are as many unique PCB library needs as there are users.

If you consider tolerance settings, units, line-widths, pad shapes, rotations, and many dozens of other settings (all configurable with the PCB Library Expert), you can create over 1,800 variations of ONE SINGLE library! We empower you to quickly build high-quality standard libraries to meet your specific needs. 5-Tier Density Variations Supported 1IPC A: Maximum (Most) Land Protrusion – For low-density product applications, the 'maximum' land pattern condition has been developed to accommodate wave or flow solder of leadless chip devices and leaded gull wing devices. The geometry furnished for these devices, as well as inward and 'J' - formed lead contact device families, may provide a wider process window for reflow solder processes as well.

2IPC B: Median (Nominal) Land Protrusion – Products with a moderate level of component density may consider adapting the 'median' land pattern geometry. The median land patterns furnished for all device families will provide a robust solder attachment condition for reflow solder processes and should provide a condition suitable for wave or reflow soldering of leadless chip and leaded Gull Wing type devices.

How To Create Component In React Js Es6

3IPC C: Minimum (Least) Land Protrusion – High component density typical of portable and hand-held product applications may consider the 'minimum' land pattern geometry variation. Selection of the minimum land pattern geometry may not be suitable for all product use categories. The use of classes of performance 1, 2, and 3 is combined with that of component density levels A, B, and C in explaining the condition of an electronic assembly. As an example, combining the description as Levels 1A or 3B or 2C, would indicate the different combinations of performance and component density to aid in understanding the environment and the manufacturing requirements of a particular assembly. 4User-defined preferences. Companies can establish a standard set of preferences to apply to all users of the PCB Library Expert!

Settings include:. Units (Mils, Micrometers, Inches and Millimeters). Pad Shape (Rectangle, Oblong, D-Shape or Rounded Rectangle). Rotation (Pin 1 Up, Left, Right or Down). Origin (Centric or Pin 1). Environment Level (Least, Nominal or Most). Silkscreen Line Width and Pad to Silkscreen Gap.

Minimum Pad to Pad Gap or Pad to Thermal Pad Gap. Paste Mask Reduction for Thermal Pads. Solder Mask Swell or Solder Mask Defined Pads.

Map Silkscreen and Assembly to Nominal body or Maximum Body.and more!! 5 Component manufacturer-recommended footprint. The Library Expert is synchronized to the latest guidelines of the IPC-7351, and IPC-J-STD-001 (Requirements for Soldered Electrical and Electronic Assemblies). You want your PCB Layout to pass the J-STD-001 standard for solder joint acceptability in the PCB assembly process. You also get the ability to migrate your entire library to future revisions or your own custom-defined requirements as well!

Why is this important? Because it ensures that everybody - regardless of experience or language - can build high-quality parts in the same standard, professional way! Improve your PCB Library skills with solder joint goal knowledge. Take the class ASAP! The PCB designer and EE engineer should have as much information about the PCB assembly process as possible for DFA (Design for Assembly).

We have been involved in IPC standards development for many years, and are intimately familiar with both, the IPC-7351 and J-STD-001. The Product Sheet (PDF) is available in a few languages: Download and install the for the PCB Library Expert to see for yourself how it can benefit you! Feel free to contact us or any of our world-wide distributors with questions or to request no-obligation demos! There are six types of licenses: - Single User USB Key (perpetual) - Network USB Key (perpetual) - Global Network USB Key (perpetual) - Single User SL (12-month based refresh) - Network SL (12-month based refresh) - Global Network SL (12-month based refresh) By default, all quotes issued are for the perpetual USB Key, our most popular configuration. Users who want to go without a USB Key (for example if installing a Network License on a virtual server), have the option of the SL license.

Single User License (USB Key) This perpetual license entitles you to install and run the software on one local computer. This solution is ideal for the PCB design contractor or companies with one PCB designer.

The Single User is licensed on USB key, and can be easily moved to any computer as needed. Contracting and/or always changing computers? No problem, we make it a snap!! Network License (USB Key) The Network License is perpetual and available for all the users you need!

It is ideal where library standardization is desired, regardless the CAD formats used. Professionals or novices can now easily create libraries according to company specification and customer requirements. The Network License is based on a network-enabled USB key that may be placed on a server or even a regular/user's computer. Once configured, when a user on the network opens the Library Expert, a license is automatically checked out from the key. When the Library Expert is closed, the license is made available for others to check out. Global Network License (USB Key) The Global Network License is identical to the Network License, but in addition also gives customer right to place the Network License on the company's globally-accessible network so it is availalbe to company users outside the location assigned to the license. Single-SL, Network-SL, and Global-Network-SL Licenses The HASP 'SL' Licenses (Single and Network) are not perpetual and expire 12 months after purchase, at which time they cease to function unless they either get Refreshed or Replaced.

Altium Designer Create Component

Refresh - renewing same License ID (on same machine, or server if a network license) - Replace - issue a new License ID for a new PC or server There will be no cost to REFRESH nor REPLACE either SL license if in conjunction with an upgrade purchase. If no upgrade is purchased and the license needs to be refreshed for a Library Expert version older than what is currently available at that time (for example refreshing a 2017 license for another 12 months in 2018 without upgrading to version 2018), the 12-month REFRESH will be subject to a non-refundable processing fee of $100. THERE IS NO GUARANTEE that older versions of the Library Expert will function as intended - or at all - with newer operating systems, patches,.NET Framework updates, etc. If the license needs to be installed on a new computer or a new activation is required for whatever reason, a REPLACEMENT license will be required, and will be subject to a non-refundable processing fee of $125; customer and PCBL may need to take steps to terminate all previously issued license(s)/activation(s) that are being replaced. A limit of 3 license replacements are allowed for each VERSION of the Library Expert for which a license is purchased, after which the licenses must be repurchased. NOTE: All costs associated with REFRESH or REPLACEMENT of SL Licenses are subject to reasonable change year to year. User Accounts User Accounts are needed to login and download the latest release of the Library Expert, as well as access POD.

Diptrace Create Component

User Accounts are limited to one (1) per Single User License, and three (3) for Network Licenses. Library Expert Professional user accounts associated with currently released version have free access (25 parts/day) to the POD database. Risk-free Purchase Before you purchase anything, you can evaluate the software to see how it works for you. It only takes minutes to evaluate!

If you have any questions or prefer a walk-through! System Requirements Microsoft Windows based computer, running Windows 10, 8, 7, or Vista., the Microsoft.NET Framework 4.0 (downloadable from Microsoft), 40MB of hard drive space, a USB port, and display resolution of 1024 x 768.Although quite a few Library Expert users have Windows XP, it is no longer supported by Microsoft and our ability to support XP is limited.